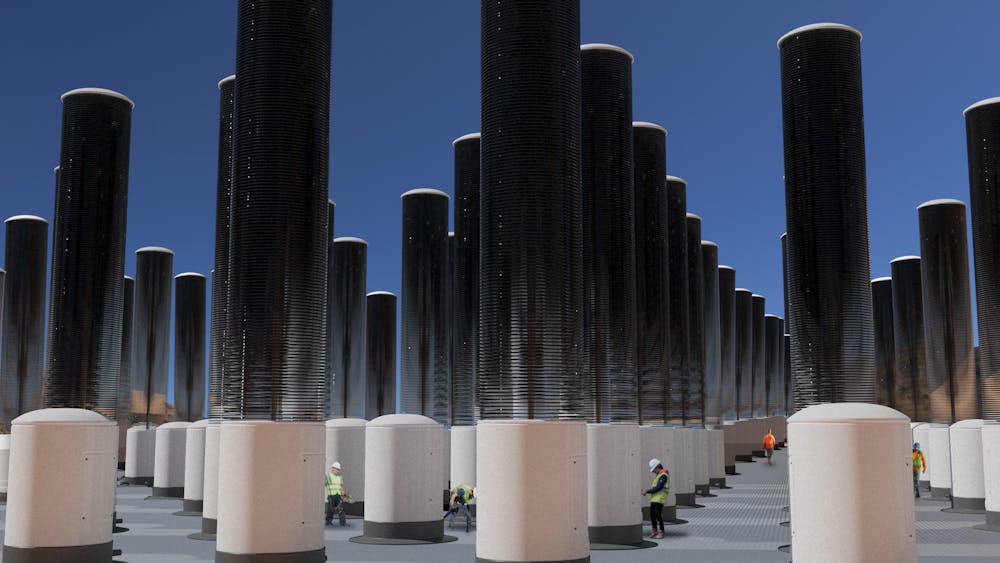

Mechanical trees aren't like something you’d see in a forest or on a front lawn — these trees stand about 30 feet tall and have a stack of 150 discs in lieu of leaves.

Like real trees, these large structures suck carbon dioxide out of the air, but they're much more efficient at performing this task. They can store the carbon they collect, removing it from the atmosphere permanently.

Mechanical trees require no energy to function and pull carbon dioxide out of the air as the wind passes through them. When the trees are full of carbon dioxide, they collapse in on themselves and keep the carbon to be stored.

A prototype will be built as early as next year at ASU. The world’s first mechanical tree will sit at the Julie Ann Wrigley Global Futures Laboratory, set to open on the Tempe campus in December 2021.

READ MORE: ASU launches new Julie Ann Wrigley Global Futures Laboratory

The inventor of these trees, ASU professor and director of Center for Negative Carbon Emissions Klaus Lackner, has been working on carbon-capture technology since the early 1990s.

This technology is a way to reduce global carbon emissions, which are a leading cause of global warming and climate change, according to Lackner.

Lackner said that not only do humans need to reduce carbon dioxide emissions, we have released so much that the carbon in the atmosphere cannot disappear naturally.

“We have enough carbon credit card debt that we have to pay at least some of that back,” Lackner said. “We need to have ways of getting carbon dioxide back out of the environment.”

Lackner said this technology would contribute to removing carbon from the air and could be commercialized while having a positive environmental impact.

ASU has teamed up with other global sustainability leaders to create Silicon Kingdom Holdings, a company in charge of commercializing Lackner’s technology.

Both the technology itself and the carbon it captures can be commercialized. Governments that want to lower their carbon emissions would be particularly interested, according to Reyad Fezzani, a director at Silicon Kingdom Holdings.

Fezzani said once the carbon is collected, it is permanently buried under the ground in a process called sequestration. The carbon dioxide itself can also be commercialized.

Carbon dioxide is used in a number of ways, namely in the food and agriculture industries. Commercial industries such as these often use manufactured carbon dioxide, adding to global emissions.

The mechanical trees would reduce the need for commercial carbon dioxide production while selling the collected carbon dioxide at a much lower price point.

According to Fezzani and Silicon Kingdom Holdings CEO Pól Ó Móráin, manufactured carbon dioxide currently costs upwards of $600 per ton.

“What we're trying to do is reduce the cost per ton to the lowest level possible, ideally below $100,” Fezzani said. “Today, carbon dioxide is manufactured at much higher prices.”

Lackner said the carbon collected by his technology might be able to bring the price down to $30 per ton.

The fuel industry could find this carbon source useful as well. The fuel industry is responsible for a large amount of global carbon emissions, according to Lackner, and it partly comes from the need to drill for natural oil and gas.

According to Fezzani, the process of refining oil and gas requires a significant amount of energy and the finished product releases even more carbon dioxide into the atmosphere. Fezzani also said, however, there are global efforts to convert captured carbon into a fuel source to reduce drilling around the world.

Once the prototype is built at ASU, the startup can begin to expand into mechanical tree farms. These farms would contain as few as a dozen trees and capture about one ton of carbon dioxide per day, Móráin said.

Eventually, the startup hopes to mass-produce these trees and establish these farms all over the world.

“It's at this stage that we start to see the benefits of the technology both on the energy system and on the capture side,” Móráin said. “It's those two elements together that bring the whole concept together.”

Correction: The photo caption for this story misstated the company's location. It is based in Dublin.

Reach the reporter at mbortega@asu.edu and follow @Marixortega on Twitter.

Like The State Press on Facebook and follow @statepress on Twitter.