Two robotics engineering students out of the Ira A. Fulton Schools of Engineering have found a way to take recyclable plastic and turn it into filament for 3-D printers.

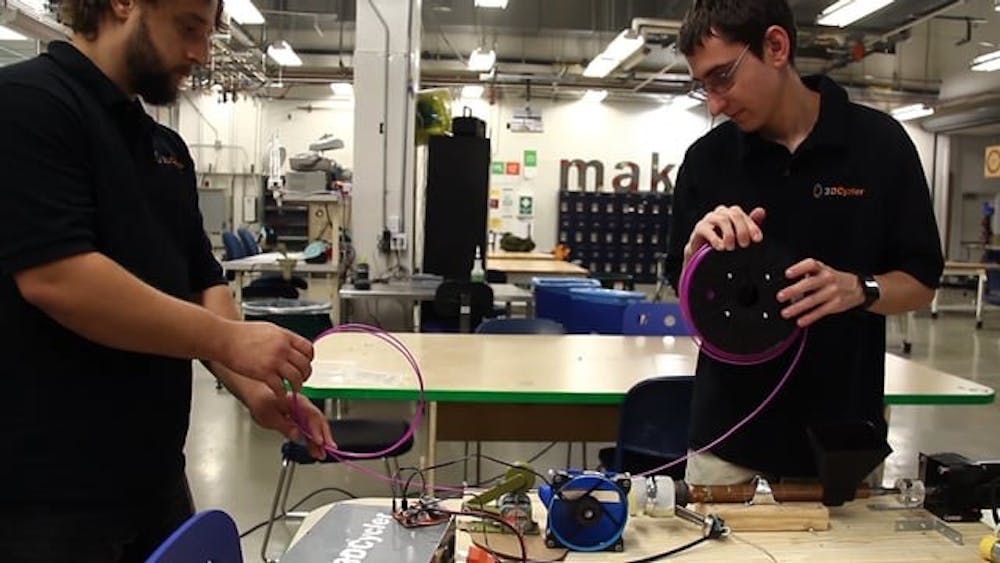

“3DCycler is a product and a system built around turning recyclable plastics like water bottles, party cups, Tupperware, anything like that, into 3-D printable filament that can be used to print new parts,” co-founder of 3DCycler and robotics Joshua Kosar said.

It all started when Kosar asked the question, “Why can’t we recycle this stuff that we have sitting around the lab?” With that, 3DCycler was born.

Kosar and his co-founder Riley Chicci started working on the idea last January.

“We started out on our own dime developing it with parts pulled together from here and there," Kosar said. “We threw the initial funding down ourselves and built on that.”

“We’re doing something weird with parts that are off the shelf,” Chicci said.

The research and development process for the original model took approximately five to six 12-hour days of work, according to Chicci.

The co-founders took their idea to a business pitch competition in downtown Phoenix.

“I actually ended up winning the pitch competition which is still kind of surreal in my mind,” Kosar said. “After a little while it started building momentum.”

As time went on, the business partners continue to rack up funding and win at different competitions across the U.S.

The 3DCycler team won the University of Nebraska-Lincoln New Global Venture Competition, beating businesses and ideas from other schools like Harvard and Stanford to make it to the final round of the TechShop Hardware Cup.

Over the summer, the team was chosen to be part of the Edson Program for fall 2015, a cohort of 21 startups out of the Edson Student Entrepreneur Initiative at ASU.

“(Edson) offers us a whole bunch of support in more ways than just financing like everything else has. They offer us access to business professionals and lawyers and that stuff,” Kosar said.

3DCycler is part of the growing entrepreneurial community out of ASU, which is supported by the Fulton Engineering Startup Center. The students were also able to use the Startup Labs based on the Polytechnic campus as a resource.

“The center is newer,” Brent Sebold, director of the Startup Center, said. “It’s an initiative to promote coursework and funding and support for entrepreneurial ventures across the six schools of engineering.”

The Startup Center got going last semester, but the infrastructure is still being completed. The focus of the center is to help student ventures and coordinate the entrepreneurship courses available.

The opening party for the center will take place on Nov. 19, during Global Entrepreneurship Week.

Kosar and Chicci were also able to make use of the Startup Labs and all of the tools within it

The makers’ lab used to be a 15,000 square foot clean room. It now holds specialty equipment for Fulton School students ranging from lasers to 3-D printers to sewing machines to one of the first 3-D metal printers.

“The sophistication of these final projects are off the chain with all of this equipment,” ASU Polytechnic Startup Labs Manager Sean Dengler said. “It used to be a clean room in a lab environment where they were doing semiconductor experiments.”

The labs were opened in 2012.

The 3DCycler team has used these tools and resources to advance their full product, which they are expecting to officially launch January 2016. This is when the first wave of devices will go out for testing.

The current initial price point that they are looking at is $1,500, although they are still doing some calculations.

“We plan on launching to them first and getting this kind of feedback loop going before we start launching to larger companies like arenas and schools and municipalities,” Kosar said. “We’re excited to change the way the maker community recycles.”

Related Links:

Students embrace 3-D printing, solve real-world problems

Local tech company set to change cars through 3-D printing

Reach the reporter at chloe.nordquist@asu.edu or follow her on twitter @ChloeNordquist.

Like The State Press on Facebook and follow @statepress on Twitter.