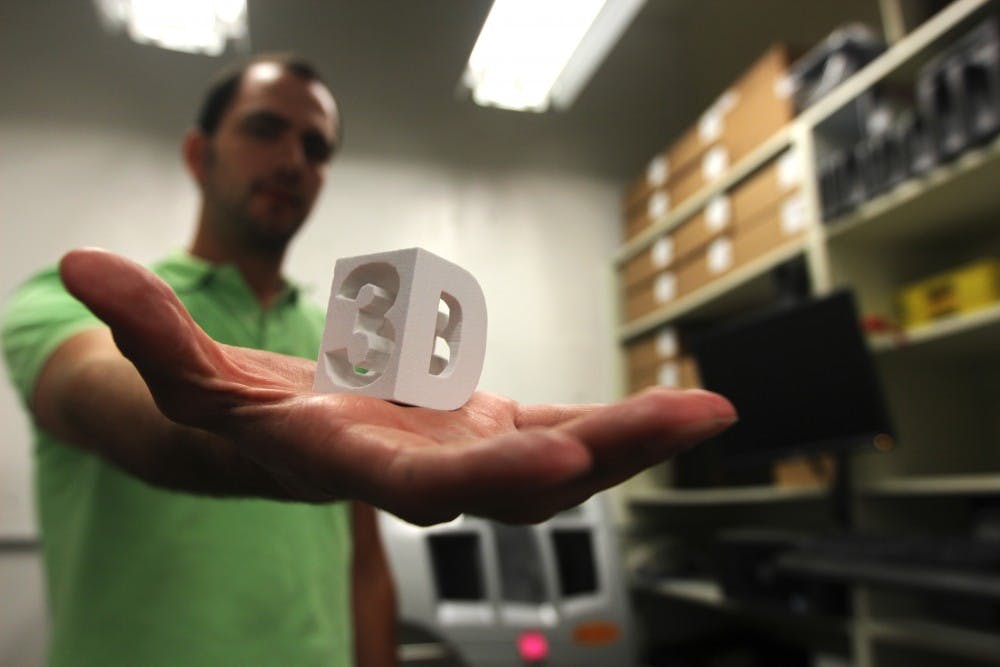

The Digital Lab, found in the basement of the design building on ASU’s Tempe campus, houses a multitude of 3D printers. Students can utilize these facilities any time they need to, and the room is also equipped with laser printers. (Photo by Dominic Valente)

The Digital Lab, found in the basement of the design building on ASU’s Tempe campus, houses a multitude of 3D printers. Students can utilize these facilities any time they need to, and the room is also equipped with laser printers. (Photo by Dominic Valente)Design studies has reached the next dimension — quite literally.

From guns to toys to body parts, 3-D printing, once the future of modern design, has become the present and ASU design students are becoming very familiar with its possibilities.

Prasad Boradkar, a design professor and the chair for the industrial design program at the Herberger Design Institute, said 3-D printing is just one form of "rapid prototyping" or "digital fabrication" that allows students to build models for everyday solutions to design challenges. "We use these technologies and prototypes to build models of things we are designing," he said. "So when the students are designing new products, we can use 3-D printing, for example, to get some physical and volumetric sense of what the product will look like, how big it will be and how the parts will fit together."

Boradker said the ability to 3-D print allows students a way to get an early vision of what their design ideas will end up looking like in the real world, and some of his students in industrial design and innovation space programs have worked on projects like designing products for individuals in wheelchairs.

"We always think of an important social need to solve," he said. "So recently, we had students answer the question, 'How do you assist people in wheelchairs with everyday tasks?'"

Building models and even working prototypes using 3-D printing is growing quickly in the design industry, and many design companies use this technology to evaluate their designers' ideas, Boradker said.

He said his students will already be familiar with the real world applications of 3-D printing once they graduate.

"Companies use this as a means of evaluating these designs from a user perspective," he said. "It has really sped up the process of product development so you can go from a simple idea to a 3-D version very quickly. You can build almost anything you want from this."

Boradker said there is an increased interest in the DIY and make-it-yourself movements of home 3-D printing and some 3-D printers are even available for purchase online for less than $1,000.

"They're getting cheaper, they're easier to work with and they are increasingly flexible," he said.

Spencer Nelson, an industrial design graduate student, said he uses the 3-D printers at ASU for his academic projects, but also has a desktop 3-D printer in his home.

Nelson can use the skills that he has acquired in his coursework at ASU, along with his 3-D printer, to help him solve problems in his home from creating spare parts for his laser cutter to making new toys for his daughters.

"My daughter thinks it's like the magic toy machine," he said. "She'll think of something and say, 'Hey daddy can you make this for me?' So It's a dream maker in some senses."

Nelson said he thinks 3-D printing will create a new marketplace that will be able to help reduce the carbon footprint as it becomes more common in peoples' homes. He said not everyone has the time to learn how to do computer modeling, but designers could make their files available for purchase.

"I think online marketplaces will develop where we can purchase files for, say spare parts or tools, and instead of us always having to go to the store to purchase them, we will be able to buy the file online and print it at home," he said.

Customized products such as rings, toys or bracelets could also create another consumer marketplace for 3-D printing, Nelson said, but it can also be used to print prosthetics and even cranial implants.

"It can do amazing things," he said. "So that is what I want people to see and know about it."

Wesley Tafoya, a graduate student in the architecture program, said design students can get real-world experience utilizing 3-D printing tools that they will use in real-world applications.

Tafoya, who works at ASU's digital laboratory where design students can do their 3-D printing, said the lab has three different types of 3-D printers, all with their own cost and quality advantages and disadvantages.

He said all of the printers, small or large, are similar to those students will come across when they graduate.

"What we do here at the digital lab is show students how to set up their files and create an object for whatever project they are working on," he said. "We help them to materialize their ideas into 3-D form using the 3-D printers, whether it be usability or just display purposes."

Tafoya said the ever-increasing affordability of 3-D printing has made it available to even the smallest design firms, which use it in the desktop form, and using 3-D printing is a crucial skill for design students.

Tafoya said he has seen students use 3-D printing to create sculptures that mimic organic shapes, or re-design traditional products, such as screwdrivers, to be more ergonomic and user-friendly.

"We want to give students the variety of anything from hands on desktop 3-D printing to the more in-depth, high-quality professional-grade 3-D printing," he said. "We can offer both here so students can get a real variety of skills and experiences depending on where they want to go."

Reach the reporter at npmendo@asu.edu or follow him on Twitter @NPMendoza